Table Formwork for Construction Concrete Poruing with Steel Floorprop or Scaffolding System

Basic Info

| Model NO. | Table form |

| Material | Steel Wood |

| Type | Slab Formwork |

| Color | Yellow, Blue or Customized |

| Length | 3300~5000 mm |

| Width | 2440~3600 mm |

| Thickness of Slab | 100~500mm |

| Bearing Capacity | 5~15kn/Square Meter |

| Auxiliary Equipment | Lifting Fork, Shifting Trolley |

| Certificate | SGS / ISO9001:2015 |

| Application | Slab Pouring |

| Transport Package | Package Box, Steel Pallet, Steel Frame, Container |

| Specification | 2440*4880mm, 3300*5000mm |

| Trademark | ZULIN |

| Origin | China |

| Production Capacity | 15000 Square Meters/Month |

Packaging & Delivery

Package size per unit product 110.00cm * 110.00cm * 110.00cm Gross weight per unit product 480.000kgProduct Description

Product DescriptionZULIN modular table formwork

The flexible and adaptable slab formwork

Introduction

Table formwork is widely used in the concrete pouring of slabs. The system is suitable for any ground plan and any floor height. It has simple structure, which makes it especially cost-effective.

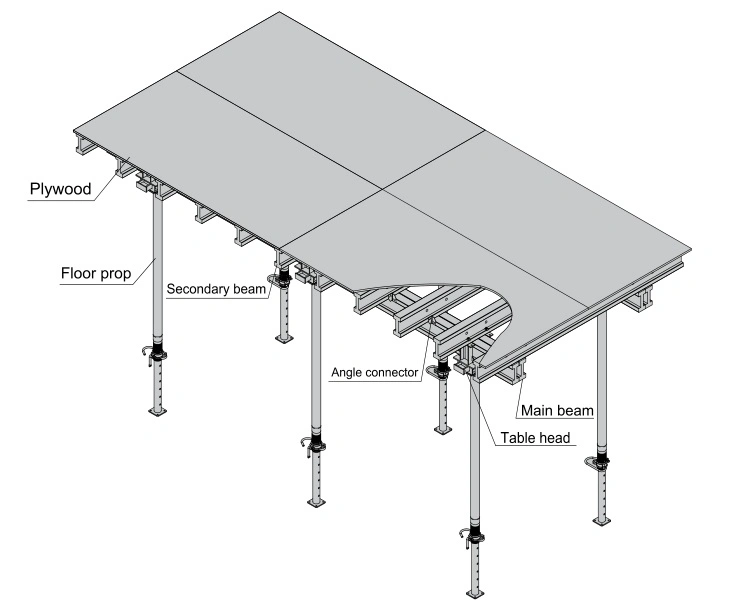

Product Sketch

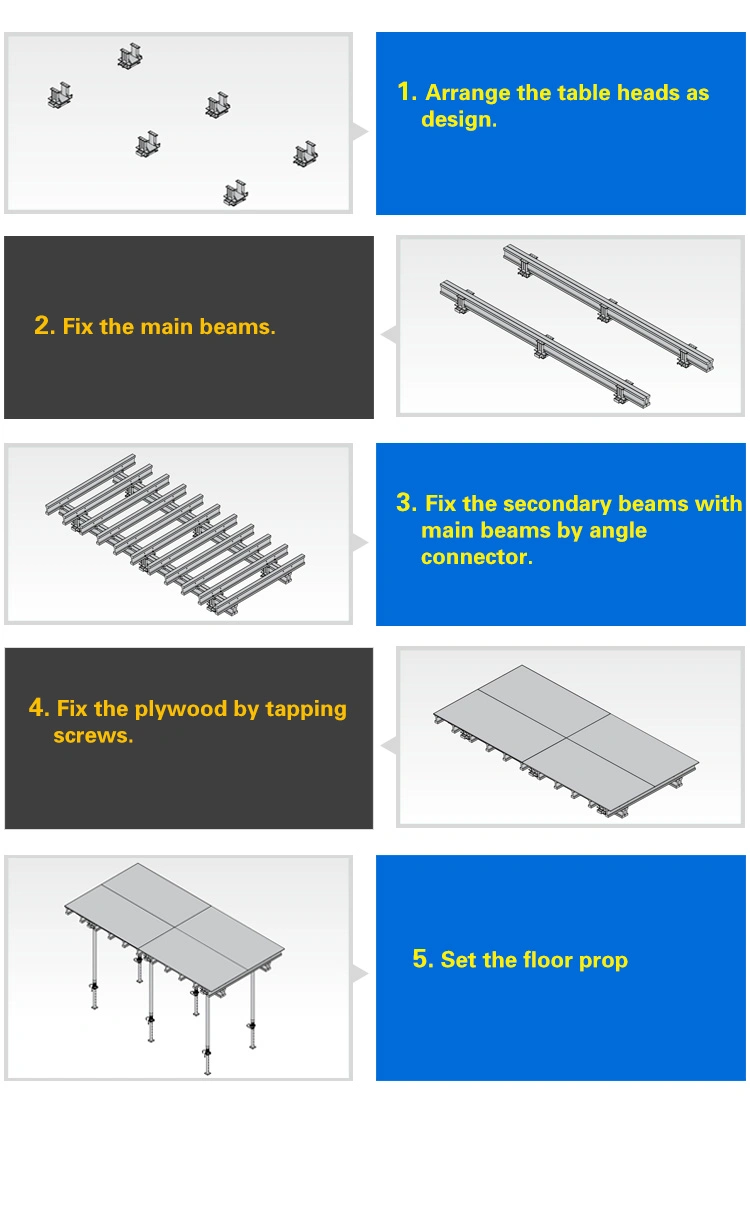

The Assembling Process

Shifting Trolley

Shifting trolley is used to transport table formwork in horizontal direction.

Parameters

| PARAMETERS | |

| Length | 3300~5000 mm |

| Width | 2440~3600 mm |

| Thickness | 250~300 mm |

| Bearing Capacity | 7.8~9.1KN/square meter |

| Bearing Load of Lifting Fork | 10~15 KN |

| Bearing Load of Shifting Trolley | 11~20KN |

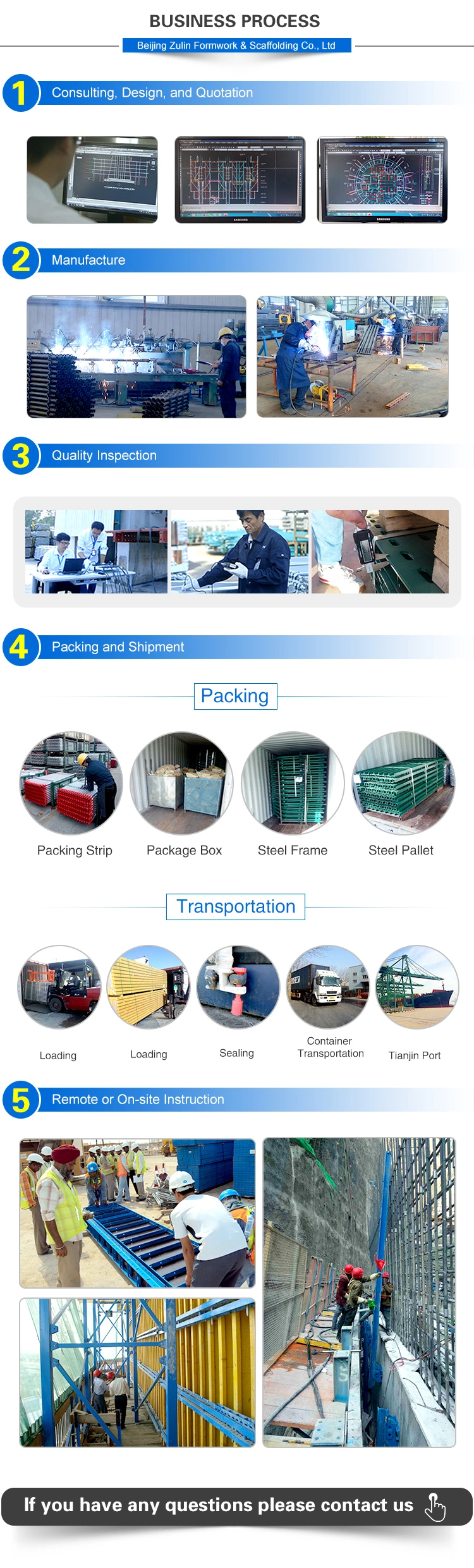

Business process

Completed Projects

COMPLETED PROJECTS

Company ProfileBeijing Zulin Formwork & Scaffolding is a leading company which develops, designs, manufactures, sells, and leases Formworks and Scaffoldings for construction projects in the field of civil and industrial engineering, roads and bridges, hydroelectric dams, nuclear power stations etc.

We are one of the pioneer companies which developed formwork and scaffolding in China. We have a team of dedicated and professional technical specialists which continuously improves our products offerings. The company have 2 excellent wooden beam production lines and 6 steel structure workshops.

With years of experiences in conducting our own research and development, we have gained recognition both in China and abroad based on our excellent techniques in this industry. We have won many intellectual properties, e.g. hydraulic auto-climbing formwork, Auto-climbing Protection Panel and many other types of formwork techniques.

We are constantly innovating in order to provide high quality products to our clients. As a result, we have received numerous compliments from our clients.

Beijing Zulin Formwork & Scaffolding is committed to our mission of striving for excellence and providing high quality products.We are dedicated to provide forward-moving technology, excellent products and services to both our existing and new clients.

FAQ

Q1. What do you do?

A: We design and manufacture formwork and scaffolding products used for pouring concrete structure in the field of housing, multi-story structure, high rise buildings, towers, sports stadiums, bridges, hydropower stations, industrial structures etc.

Q2. How many construction projects have you accomplished?

A: 600 both in China and abroad.

Q3. Have you accomplished any landmark?

A: Yes, we have. For example, PAFC (660 meters tall), The 21 Century Building, 2008 Beijing the Nest Main Stadium, CCTV New Site, Colombo Lotus Tower(Sri Lanka), Hong Kong-Zhuhai-Macau Bridge, Gezhouba Pubugou Hydropower Station etc.

Q4. What can you do for us?

A.We offer our suggestions, drawings of formwork layout, and quotations to the owners, design institutes, or contractors of the construction projects.

B.We sell our products to the contractors, building companies, or trading companies

C.We support our worldwide peer companies with our outstanding formwork or scaffolding products.

D.We provide remote or on-site instruction to the builders.

Q5. What do you need in order to make a brief design and quotation when we have a construction project to be built?

A: Structural drawing and section drawing.

Q6. How long does it take to make a brief design and quotation after we offer the structural drawing?

A: In general, it takes 5~7 days based on specific requirements of construction project.

Q7. How long dose it take to manufacture the products after the signing of contract?

A: In general, it takes 30~60 days based on the type and quantity of products to be produced.

Q8. Are your products available for leasing?

A: Our products are available for leasing in Indonesia, Singapore, Dubai, Australia, New Zealand. It depends on local relevant regulations in other countries.