Silicone Electric Pressure Cooker Parts Sealing Ring Gasket

*Product Description :1. Made from food-grade silicone material2. Convenient as you can use silicon tint brush in a dish;

Basic Info

| Model NO. | Fly-2021060307 |

| Shape | O-Ring |

| Performance | Wear |

| Standard | Standard, Nonstandard |

| Color | Clear, Black, Red, Green |

| Packaging | Carton or as Your Required |

| Shipping Type | by Air or by Sea |

| Function | Sealing Effect |

| Drawing Format | Dwg/Dxf/Igs/Step/ and Pdf |

| Forming Way | Injection Moulding, Extrusion |

| Density | 1.0-2.0mm |

| Transport Package | Customized |

| Specification | 3L, 4L, 5L, 6L |

| Trademark | Flying |

| Origin | Chinese |

Product Description

*Product Description :1. Made from food-grade silicone material2. Convenient as you can use silicon tint brush in a dishwasher or dish drying machine3. Prevents taste transfer and unpleasant soup leaks4. Non-toxic and eco-friendly5. Pressure Cooker Seal, Gasket, washer, spacer, 100% food grade6. Be widely used for a pressure cooker, rice cooker, etc7. FDA and LFGB material rubber seal8. Size: 16/18/20/22/24/26/28/30CM diameter

Feature:

1. Good elasticity2. Good anti-ozone, anti-aging3. Good weather resistant4. Good fire and water-resistant5. Convenient installation6. Shiny appearance7. Many colors are suitable8. Good tight dimensional tolerances and have excellent compressibility, elasticity, and adaptability to uneven surfaces.

| Material | 100% food-grade silicone, can pass FDA, LFGB test |

| Size | Design and size same as OE part |

| Surface | Beautiful looking to OE standard |

| Package | A: Inner plastic bag+ outer neutral carton B: Inner neutral box+ outer carton C: Customized packing |

| Delivery | A: 3-7days if have stock B: If not stock,15-25days for LCL shipment,25-40days for container shipment |

| Warranty | 100% inspect products before delivery |

| Payment | A:30% deposit and balance pay against BL copy B: TT, L/C, Western union |

| Certificate | All the products are produced under the ISO system |

| Sea Port | Xiamen, Fujian, China |

| Service | 1.OEM service: Can develop product according to your sample or drawings 2.Design catalog as per clients' request to help you develop new market3.Customized packing with logo 4. Arrange shipment to your warehouse |

Silicone products characteristics

1. Resistance to high temperature: At 200 ° C for long-term use, at -60 ° C still under elastic2. Electrical insulation: Silicone excellent dielectric properties, especially the dielectric propertiesat high temperatures much higher than normal organic rubbers, dielectric strength in the rangeof 20-200 ° C almost independent of temperature3 . Excellent resistance to weather, ozone, and ultraviolet radiation resistance properties, long-term outdoor use without cracking occurs. Silicone rubber can be generally considered more than 20 years in outdoor use.4. Excellent high-temperature compression set5. Good processing performance, easy molding, etc., through the hot air vulcanization extrusion molding, mold, and molding, cast molding methods such as production plus a variety of products.

How to care

Before use, be sure to wash silicone bbq brush using a sponge soaked in dishwashing detergent.After use, wash silicone bbq brush well using a sponge soaked in dishwashing detergent and store after wiping off any moisture.Dishwasher or dish dryer safe.

Payment and Shipping : 1. Payment terms: Bank TT, Paypal, West union2. Shipping way: Via Air, by sea, or by FedEx/DHL/TNT/UPS

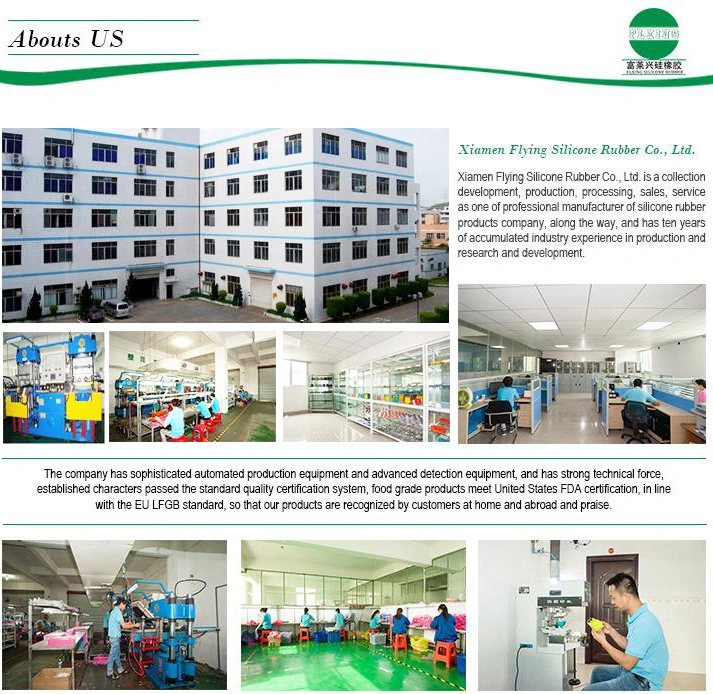

Our company's strength :1. All material is of RoHS and REACH approved2. Precision Own Mold-Making Technology 3. A manufacturer with Mold-Making Plant, Silicone Compression Plant, Assembly Plant4. Production and Test strictly according to ISO90015. Experienced Designers and Engineers6. Test Equipment: 3D Projectors, Elasticity Measurement, Durometer, etc 7. Background of OEM service for PHILIPS, FOXCONN8. Ability to handle numerous small to MID-size projects9. Rapid Reaction Organization: Support customer within a short time

Packing :

1 PC / opp bag , 250 pcs / cartonCarton Measurement :40 x 30 x 35

Quickly Quotation Requirements:

| 1. | Offering 2D/3D design drawings, Samples or other basic information | |

| 2. | Materials Demands: | |

| 3. | Sizes Tolerance Demands: | |

| 4. | Hardness Demands: | |

| 5. | Color Demands | |

| 6. | Mold Life Demands, Mold Steel Demands | |

| 7. | Surface Demands | |

| 8. | Order Quantity | |

OEM/ODM Service:1. Quickly Quotation Demands: 2D/3D designs Drawings, Samples, or other basic information2. Materials Demands: LSR(Liquid Silicone Rubber); Silicone Rubber:NBR, SBR, EPDM, HNBR, TPU, PTV, NR, CR, Silicone, etc.3. Materials Hardness: 15 Shore A - 90 Shore4. Sizes Tolerance: +/-0.005mm - +/-0.3mm5. Special demands: like Surface, Color, Anti-Fire/Dust/Water, Working Temperature, Sign NDA etc,Pls feel free to communicate

Special Demands: 1) IP grade (dust/waterproof grade, 3M gumming tape)2) Anti-Fire grade (flame retardant)(UL94 VO), 3) Medical/food standards(FDA PTFE), (If really need up to completely food/medical standard, the best choose LSR)4) SGS reports etc.

You may also like

Send inquiry

Send now