Polytetrafluoroethylene Micro-Powder Grease, Dry Lubricant, Ink, Paint, Thermoplastic, Thermosetting Plastic Additives

Basic Info

| Model NO. | HaoRu |

| CAS No. | 9002-84-0 |

| Formula | 204-126-9 |

| Material | PTFE |

| Usage | Engineering Plastics |

| Plastic Properties After Heated | Thermoplastic Plastics |

| Plastic Forming Method | Extrusion |

| Color | White |

| Transport Package | Woven Bag |

| Specification | 25 kg/bag |

| Trademark | HaoRu |

| Origin | China |

| HS Code | 3904610000 |

| Production Capacity | 50000 Ton /Month |

Product Description

PTFE high quality granulation material

The PTFE spherical particles have the characteristics of smoothness, toughness, strong fluidity, high performance density, controllable particle size, no dust, easy transportation and storage, and are suitable for automatic continuous production, about manpower, and reduce human error. Polytetrafluoroethylene (suspended dispersion modified) granulation series products are pure material particles, color material particles, filler particles / powder: filled glass fiber, glass beads, copper powder, graphite, molybdenum disulfide, carbon fiber, stainless steel more than 100 varieties of ceramics, polyphenyl esters, custom or processing materials.

PTFE pure material particlesPTFE granules have superior flow properties, spherical particles, smooth surface, no dust, easy to store, high temperature, no agglomeration, suitable for automated continuous production, about manpower, reducing human error.

| Category specification | Fine powder | Medium granularity | Granulation | |

| Particle size(um) | 16~30 | 110~150 | 350~750 | |

| Performance density(g/L) | 330~380 | 400~600 | 800~830 | 830~850 |

| fluidity | Bad | Free flow | ||

| Standard relative density(g/L) | 2.13~2.19 | |||

| Elongation at break(%) | 350~420 | |||

| Tensile Strength(MPa) | 36~39 | |||

| Application | Manual operation of small and medium molded products | Suitable for automated continuous production, all kinds of molded products, precision foreign products, large parts | ||

PTFE filled powder / granules

The PTFE filler is filled with different special materials such as glass fiber, glass beads, copper powder, graphite, molybdenum disulfide, carbon fiber, stainless steel, ceramics, polyphenyl ester, etc. to show superior performance. Filled into uniform dispersion, superior performance, variety of filling types, or processing according to customer.

| Filled contend | Content(wt %) | Special feature |

| Glass fiber | 10% 15% 20% 25% | Low creep, high wear resistance, good electrical properties |

| Glass fiber + Molybdenum disulfide | 15%+5% | High wear resistance, low friction, low creep |

| Copper powder (cyan/yellow) | 40% 60% | Low creep, high thermal conductivity, high hardness |

| Carbon powder | 15% 25% | Low creep, high wear resistance, high PV value |

| Copper powder + graphite | 35%+5% | Low friction, low creep, chemical resistance |

| carbon fiber | 5% 10% | High wear resistance, corrosion resistance and high PV value |

| stainless steel | 25% 45% 50% | High withstand voltage, low cold flow, high thermal conductivity |

| P O B | 10% 15% 25% | High temperature resistance, compression creep resistance, wear resistance, especially in water, showing extremely significant wear resistance |

| PEEK | 10% 15% 25% | Wear-resistant, high temperature resistant, high lubrication |

PTFE lubricated ultrafine powder

Lubricating powder is treated with irradiation for crushing treatment, which is easy to disperse in rubber, thermoset plastic, thermoplastic, grease, ink and oil, and it is not agglutinate, non - forming, and improves its lubricity and reduces wear, friction.

| Item | The average particle size(um) | Performance density(g/L) |

| Irradiated ultrafine powder | 2~5 | 230~260 |

| Pre-sintered ultrafine powder | 5~8 | 300~320 |

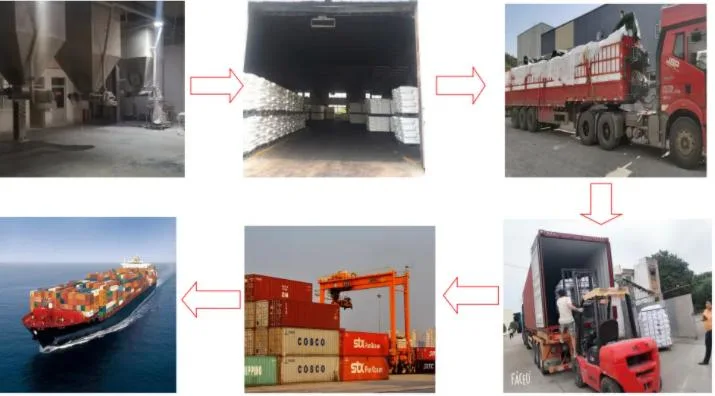

To better ensure the safety of your goods, professional, environmentally friendly, convenient and efficient packaging services will be provided.Company ProfileHebei Haoru Import and Export Trading is located in Xingtai City, Hebei Province. This company is a large modern company. The main business scope is the export of plastic particles and office supplies. In recent years, the company adhering to the concept of customer development, adhere to development, accelerate industrial transformation and upgrading, vigorously implement the technology innovation strategy, put forward a series of industry-leading technology innovation. After years of efforts and development, it has a certain scale and strength. Now has a technical service team, with excellent quality, professional service, safe technical services to provide users with higher strength, better products and services. Thanks to the high quality of our products and reasonable export prices, this will lay the foundation for our strong technical capabilities and market presence in the Americas, Africa and the Middle East, mainly in continental Europe.FAQ

Your questions:

Q1. What is your terms of payment?

A: T/T will usually be accepted,details could be negotiated.

Q2. What is your terms of delivery?

A: FOB, CFR, CIF, DDU,EXW

Q3. How about your delivery time?

A: Generally, it will take 10to 20 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q4. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings.

Q5. What is your sample policy?

A: we could offer the sample for free charge but do not pay the cost of freight.

Q6. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery

Q7: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them.

Generally, It will take 10 to 20 days after receiving your advanced payment. The specific delivery time depends on your items and quantity of your order.