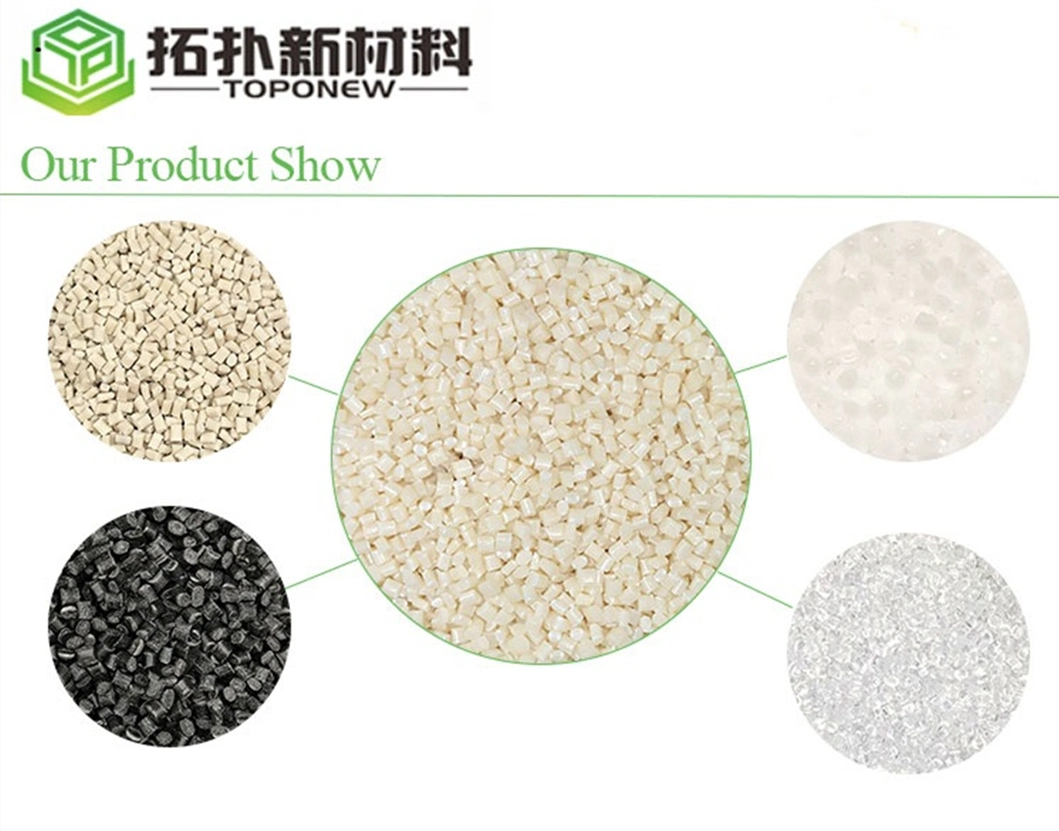

Polyolefin Filler Masterbatch Plastic Filler Masterbatch Additives

Basic Info

| Material | Resin |

| Usage | Extrusion |

| Plastic Properties After Heated | Thermoplastic Plastics |

| Plastic Forming Method | Injection |

| Color | Customed |

| ODM/OEM | Accept |

| Sample | Avaiable |

| Shape | Pellets, Granules, Particle |

| Advantage | Biodegradable, Environmental |

| Carrier | PP PE |

| Transport Package | 25kgs/Bag |

| Specification | 65*40*15cm |

| Trademark | TOPO NEW |

| Origin | China |

| HS Code | 390740000 |

| Production Capacity | 100kgs/Week |

Product Description

Polyolefin filler masterbatch plastic filler masterbatch additivesIntroduction: PO TPXCH3 is a kind of low-smoke halogen-free flame retardant polyolefin wire and cable materials.PO TPXCH3 has excellent mechanical, electrical and processing properties, high flame retardant. This material does not emit halogen acid gas, toxic and corrosive gases and low smoke under fire condition. Main Applications: Wire and cable

| Properties | Test Methods | Units | TPX150F-W1 | ||

| Density | ASTM D 792 | g/cm3 | 1.33 | ||

| Shore hardness D | ASTM D 2240 | - | 49 | ||

| Tensile strength | IEC 60811-1-1 | MPa | 13 | ||

| Elongation at break | % | 321 | |||

| Ageing condition 180ºC×168 h | Tensile strength retention | IEC 60811-1-2 | % | 95 | |

| Elongation at break retention | % | 62 | |||

| Thermal extension(200ºC, 0.2MPa,15min) | Elongation under load | IEC 60811-2-1 | % | 45 | |

| Permanent deformation after cooling | % | 3 | |||

| -25ºC Low-temperature shocks | IEC 60811-1-4 | - | PASS | ||

| Flame retardant properties | UL1581 FT-2 | -- | PASS | ||

Combustibility:

| Properties | Test Methods | Units | TPX150F-W1 |

| Oxygen index | ASTM D2863 | % | 29 |

| Smoke density (Flame) | ASTM E-662 | -- | 83 |

| Smoke density(No Flame) | -- | 289 | |

| pH | IEC 60754-2 | - | 5.2 |

| Electroconductibility | μS/mm | 2 | |

| Toxicity index | NES 713-1985 | - | 1 |

| Halogen gas content | IEC 60754-1 | mg/g | 0 |

Other performance:

| Properties | Test Methods | Units | TPX150F-W1 |

| Dielectric strength | IEC 60243 | kV/mm | 36 |

| Mass resistivity(20ºC) | IEC 60093 | Ω.m | 1.5×10 13 |

| Thermal shock(180ºC×1h) | IEC 60811-3-1 | - | PASS |

| Thermal contraction (100ºC×1h) | IEC 60811-1-3 | % | 1.0 |

| Gate | Die | Neck | Zone 3 | Zone 2 | Feed |

| 150ºC | 150ºC | 145ºC | 135ºC | 120ºC | 100ºC |

In order to ensure the smooth surface of PO TPX150F-W1 extrusion material, a screen should be added when extrusion. Screen generally 2 Layer,80 mesh ~100 mesh is appropriate.

We are a manufacturer.

About Sample?

5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?Quality is the Priority, we always pay great importance to quality from beginning to end, we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? is the sample free?

7-10 days to send free samples by DHL, TNT, UPS