Decoloring Agent (DCA) of Textile and Dyeing Waste Water Treatment Chemicals

CAS No.: 55295-98-2 Product Name: BWD-01 water decoloring agent polymer Chemical Name: Dicyandiamide formaldehyde resin ;

Basic Info

| Model NO. | BWD-01 |

| Type | Sewage Treatment Chemicals |

| CAS | 55295-98-2 |

| Purity | 50% |

| Grade Standard | Industrial Grade |

| Application | Water Treatment(Color Removal for Wastewater) |

| Transport Package | 30kg Pail, 250kg Plastic Drum, 1250kg IBC |

| Specification | SGS |

| Trademark | Bluwat |

| Origin | Jiangsu |

| HS Code | 38099100 |

| Production Capacity | 50000/Year |

Product Description

CAS No.: 55295-98-2Product Name: BWD-01 water decoloring agent polymer

Chemical Name: Dicyandiamide formaldehyde resin

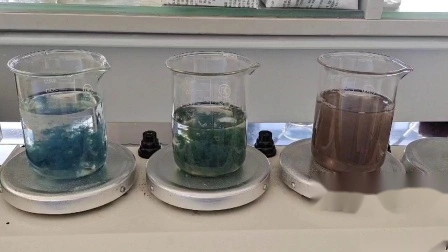

This product is a quaternary cationic polymer which is specialized product to treat effluent for color removal, flocculating and COD decreasing.

Application field:

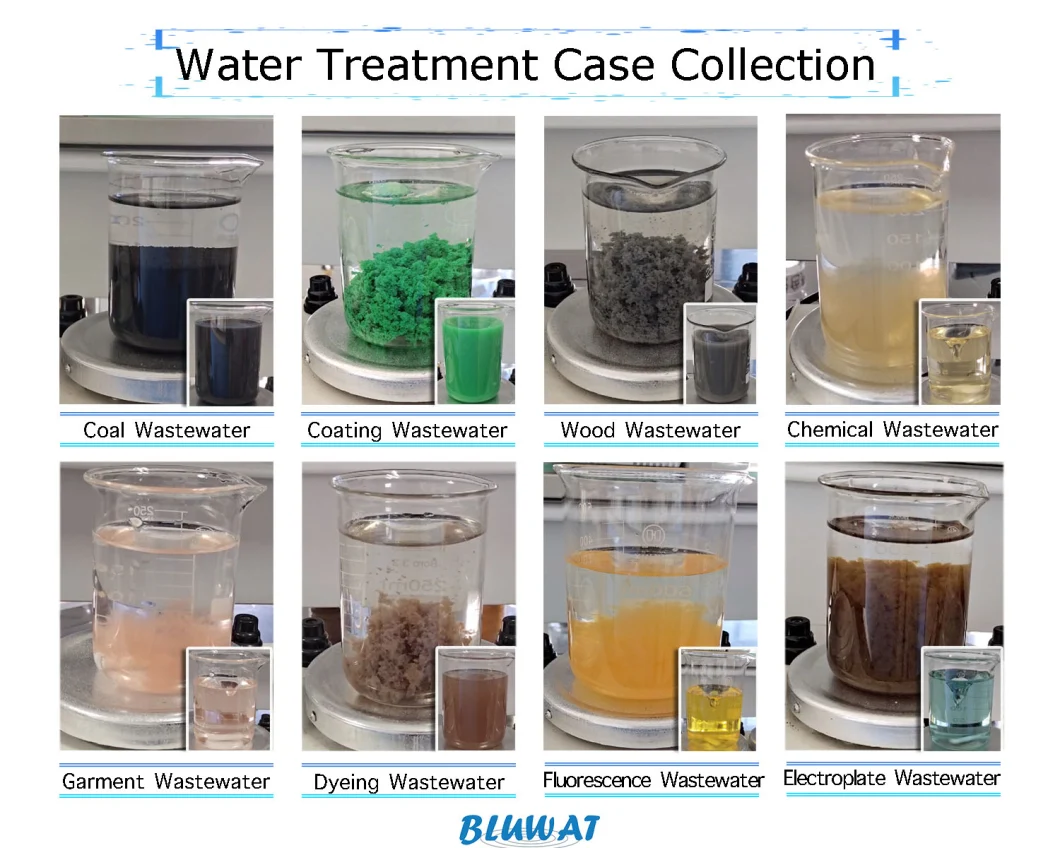

1, It is mainly used for color removal treatment for high-colority wastewater from dyestuffs plants. It is suitable to treat wastewater with actived, acidic and disperse dyestuffs.

2, It can also be used to treat wastewater from textile industry and dye houses, pigment industry, printing ink industry and paper industry.

3, It also can be used in the production process of paper&plup as rtention agent.

Specificationa:

| Specifications: | BWD-01 Water Decoloring Agent |

| Appearance: | Colorless to yellowish translucid liquid |

| Solid Content: | ≥50% |

| Specific Gravity at 20°C: | 1.1-1.3 |

| PH Value (30% Solution): | 3-6 |

| Storage Temperature: | 10-30 (oC) |

| Viscosity(25°C,cps): | 30-300 |

| Solubility: | Soluble With Water at Any Rate |

Application methods:

1, Dilutes with 10 - 40 times water and then dosed into the waste water Directly, after being mixed for several minutes, it can be precipitated or Air-floated to become clear water

2, pH index of the waste water should be adjusted to 7 - 10 for better Result

3 If colority and COD are relatively high, it can be used with the help of Polyaluminum chloride to reduce treatment cost, whether polyaluminum Chloride is used before or afterwards depends on the flocculation test And the treatment process

Package and Storage:

1, It is harmless, non dangerous material

2, It can be stored at room temperature, can not be placed in the Sun

3, 25kg pails, 250kg plastic drums and 1250kg IBC tank.

Application technical information in Europe The dyehouses are divided in 2 categories: A. When they have biological treatment first and after they make chemical treatment. In this case they use: 70-80 ppm BWD-01 15-20 ppm Polyaluminum Chloride 1-2 ppm Anionic polyacrylamide First we apply the PAC (contact time 3-5 min with the waste water), after then BWD-01 Water Decoloring Agent (contact time 5-10 min), and after then anionic polyacrylamide. It will give too much economy if we'll adjust the pH 7-8, otherwise the consumption of BWD-01 will be ~20% higher. B. When the treat first by chemicals, then the usual dosages are : Adjustment the pH 7-8 80-100 ppm BWD-01 10-20 ppm PAC 1-2 ppm Anionic polyacrylamide

You may also like

Send inquiry

Send now